Audi Garage Leicester

Short Overview

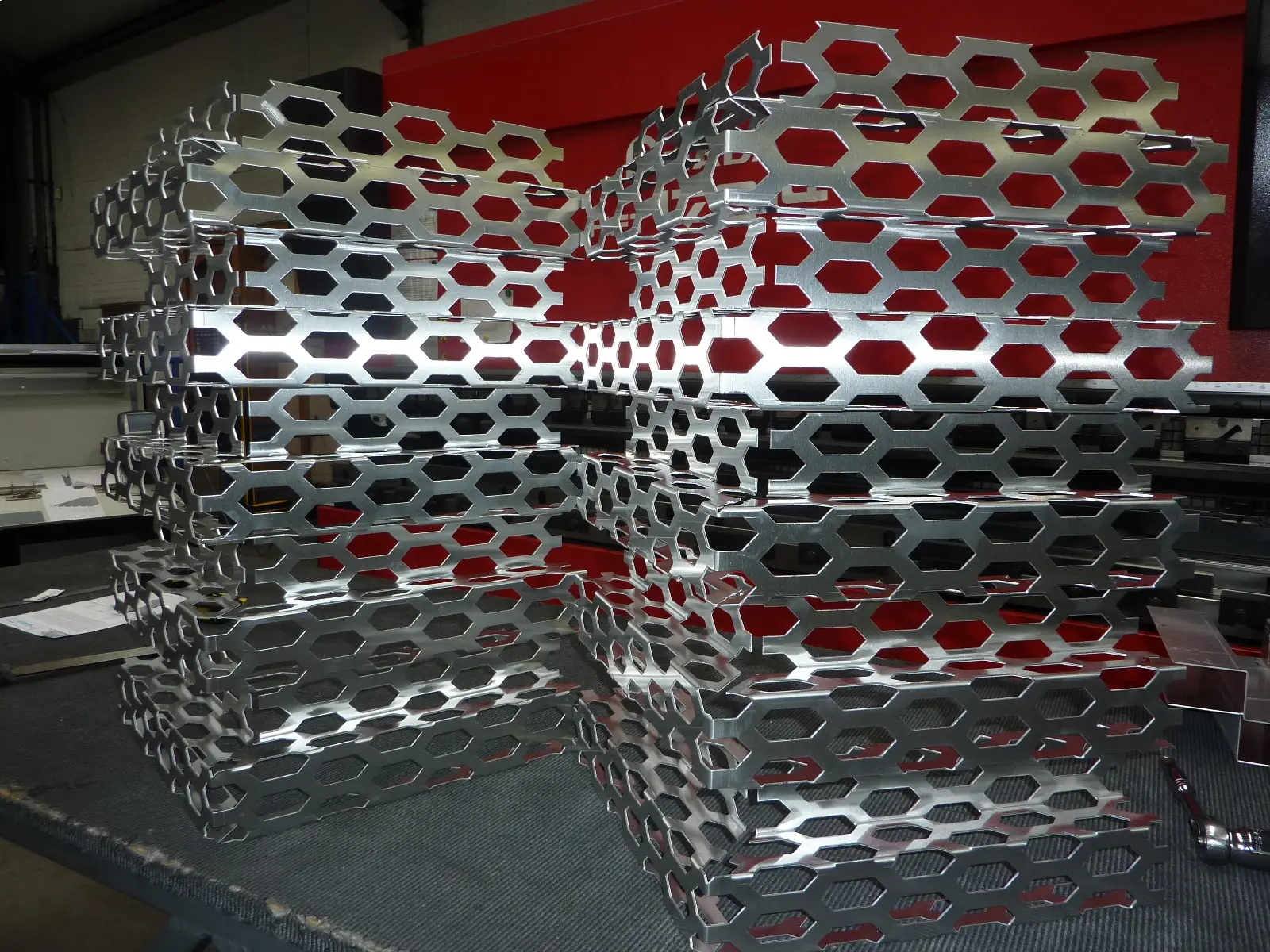

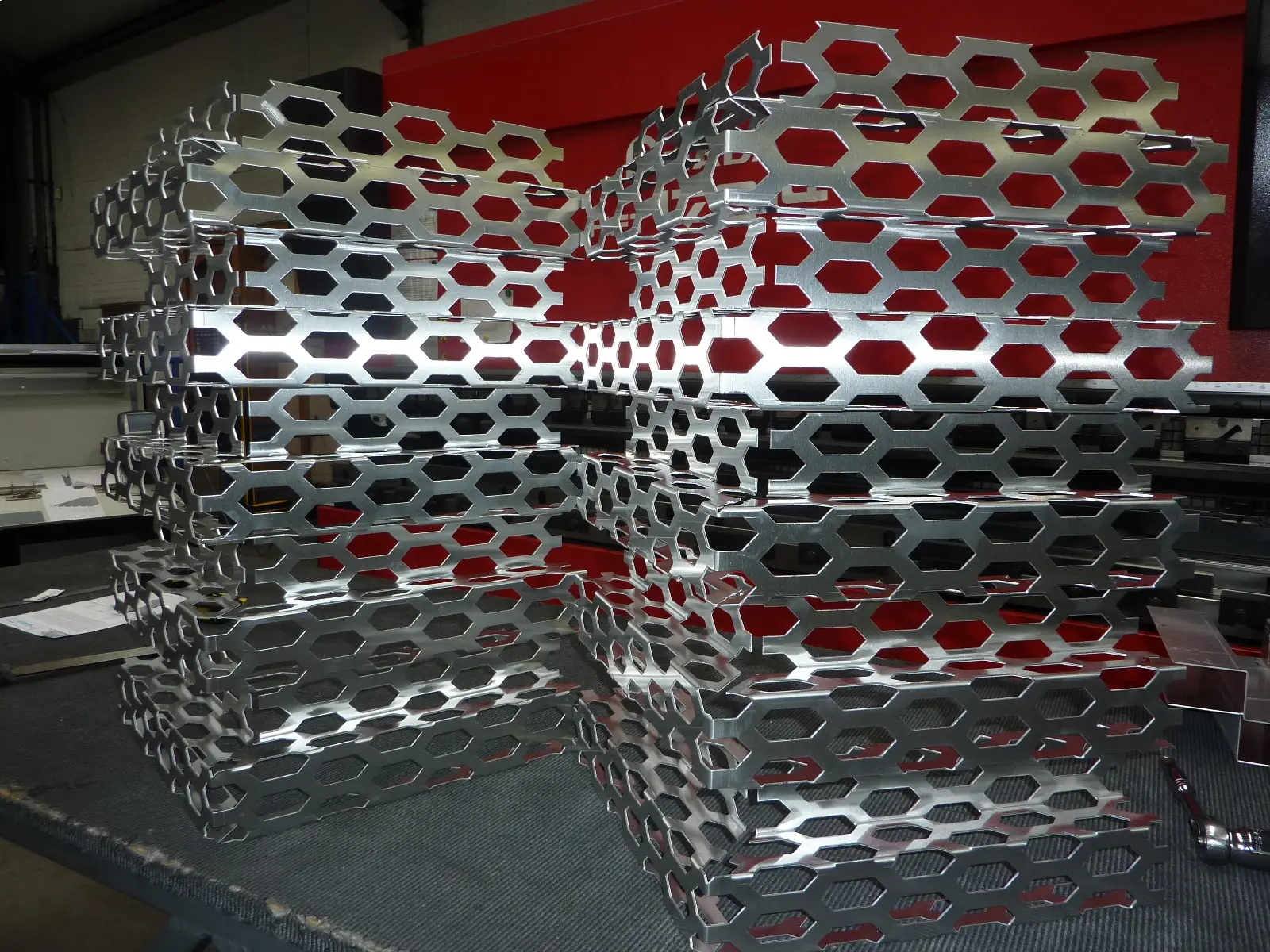

We were briefed with fabricating perforated cladding and decorative components for a few car garages with a unique aesthetic consisting of complex bends and elongated hexagonal perforations. The garages are located in England so transport was a key factor in our planning. All components would have to fit within shipping dimensions for assembly across the Irish sea.

Project Description

A challenge arose in the area of corners. The profile of the cladding meant that all corners would have to be mitered to fit each other but the perforated pattern would also need to be aligned perfectly and welded at each intersection. We redeveloped the design in such a way that we could fold the corners together to minimise the amount of welding to speed up the process of manufacturing.

Our Solution

To create the elongated hexagonal perforations we had to have new custom tooling made specifically for this job. Creating a new punch and die meant that all the perforations could be punched in a single operation which drastically reduced the duration of each panel on the punch machines.

We redesigned various other components of the buildings to allow them to be more efficiently fabricated in single pieces rather than producing multiple individual parts to be assembled on site. This saved time for everybody involved.