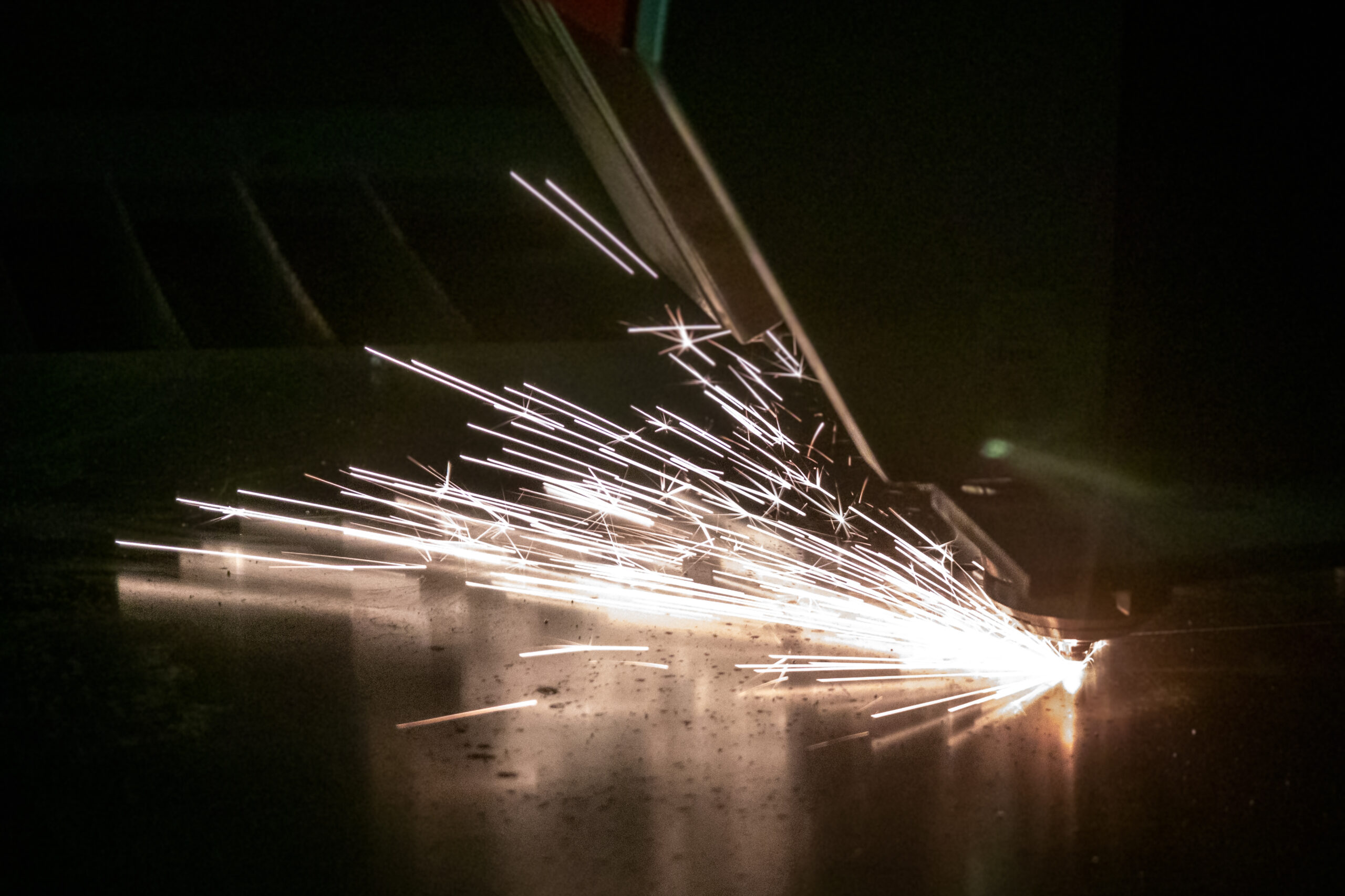

Laser Steel Cutting Services

Our laser-cutting services showcase cutting-edge precision and versatility. With our advanced laser cutting technology, we can deliver intricate and precise cuts within a wide range of steel materials. The intense and focused beam of our fibre laser enables us to swiftly and accurately cut through stainless steel, aluminium, copper, and more, creating seamless and smooth edges with minimally affected zones.

We Can Tailor To Materials Of Various Thicknesses:

- Mild Steel Laser cutting: up to 25mm

- Stainless Steel Laser cutting: up to 20mm

- Aluminium Laser cutting: up to 12mm

- Maximum Sheet Size: up to 4000mm x 2000mm

Cutting-Edge Laser Technology

Our advanced technology enables effortless cutting through various metals, including stainless steel and aluminium, allowing for intricate designs and smooth finishes. Pairing high-end modern machinery with tech-specific design software like CAD and Solidworks allows us to optimise our production line to always perform at its best.

Our fibre laser has a maximum size of 4m x 2m, allowing for precise cuts on materials up to 15mm thick. For larger projects, our laser can handle sizes up to 8m x 2m and materials up to 6mm thick.

Quality Assurance

From ideation to delivery through the various stages of production, our work is quality-controlled, with measurements and requirements frequently assessed throughout the production process. Our commitment to rigorous quality control ensures our customers receive flawless sheet metal products that meet their exacting requirements every single time.

Customisation: Tailored Sheet Metal Solutions

Our top priority at EliteForm is ensuring customer satisfaction through liaising with our customers. By working closely with our clients, we gain a deep understanding of their project’s unique requirements, allowing us to tailor every aspect of the products to their bespoke specifications. Throughout the process, we actively involve our customers, ensuring that the result meets and exceeds their expectations, delivering complete satisfaction.

FAQ

What is laser cutting and how does it work?

Using a focused, intense laser beam, we can accurately cut through various sheet metal materials and densities. Such a concentrated beam allows acute accuracy and precise shapes bespoke to the customer’s requirements. The information between the material and the machine is transferred via advanced software and is meticulously drawn up by our drawing staff.

How accurate is your laser cutting service?

AMADA’s original Auto Collimation technology can precisely control the laser beam spot size and focus position, allowing the seamless removal of molten metal from within the kerf of the cut. Repeatable positioning accuracy mm ± 0.01.

What materials can you cut?

- Mild steel

- Stainless steel

- Aluminium

- Galvanised steel

What type of machinery do you use?

We utilise AMADA technology and machines. Our primary lasers are the Amada Ensis AJ series with laser and fibre laser capabilities.

Do you use a fibre laser to cut materials?

Yes. In addition to our larger laser, we also operate a fibre laser from the Amada Ensis range. This machine is very energy efficient and faster at production for demanding jobs.

What are your laser-cutting capabilities?

- Mild Steel Laser cutting: up to 25mm

- Stainless Steel Laser cutting: up to 20mm

- Aluminium Laser cutting: up to 12mm

- Maximum Sheet Size Up to 4000mm x 2000mm